Назначение

423450, Республика Татарстан,

г. Альметьевск, ул. Индустриальная, 29б

equipment for the oil and gas industry

Назначение

Function.

Horizontal pumping units (HPU) are designed for pumping liquids into wells in systems for maintaining reservoir pressure in oil wells, pumping liquids of various compositions and recycling associated water.

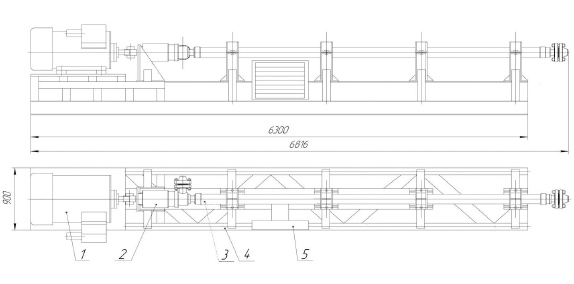

GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.

The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.

The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.

A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.

The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.

Maximum efficiency with minimum power consumption!

Advantages of GNK:

High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.

Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.

Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.

GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Высокая эффективность насоса составляет более 68%, а МРП - в 2-3 раза больше, чем аналогичные насосы ЦНС, широкий диапазон регулирования скорости впрыска и давления, а также плавный пуск и остановка ГНК.

Гибкость системы - при демонтаже или установке секции насоса, соответственно, мы можем изменять производительность и давление устройства на месте без дополнительных затрат.

Удобны в эксплуатации, поскольку вся установка на раме с отсеками и секциями может быть легко демонтирована, не требует усиленного основания, а уровень вибрации в 3-4 раза ниже, чем у аналогичных насосов ЦНС.

ГНК - полностью закрытая система, исключающая утечку перекачиваемой жидкости из резервуара в машинный зал БКНС или на открытую площадку, где установлена установка.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.

Function.Horizontal Pumping Complexes (GNK) are designed for injecting liquid into wells in order to maintain reservoir pressure of oil wells, utilization of associated water.GNK consists of a horizontal electric centrifugal pump, mounted on a metal frame with an asynchronous explosion-proof electric motor, coupling, input chamber, unloading persistent knot. Depending on the configuration the GNK can additionally include a cooling system, flexible inlet and outlet hoses, piping with a filtration system and backpressure valves.The three-phase asynchronous electric motor provides the pump drive. The rotational speed of the motor shaft is 2975 – 4106 rpm.The unloading knot (entrance module) is designed to remove the axial loads of counterpressure transmitted from the pump section.A corrosion-resistant horizontal pump provides liquid forcing. The recommended pressure on reception of the pump is from 0,05 to 4,0 MPas (is considered individually to each technological process). Rotation shaft frequency of the pump is 2975 – 4106. Efficiency of the pump is up to 75,9%.The frame assembly is designed for locating the nodes of the GNK and ensures their alignment and reliable fastening.Maximum efficiency with minimum power consumption!Advantages of GNK:High efficiency of the pump is more than 68% and MRP 2-3 times more than similar CNS pumps, a wide range of speed regulation of injection and pressure and also smooth start-up and a stop of GNK.Flexibility of system – during the dismantling or installation of the pump section, respectively we can change productivity and pressure of the unit on the place, without additional expenses.Are convenient in service as all installation is on a frame with lodgments and sections can be dismantled easily, don’t demand the strengthened base and also the level of vibration is 3-4 times lower than similar CNS pumps.GNK is completely closed system excluding any leak of the pumped-over reservoir liquid to the BKNS machine hall or on the open area where installation is placed.