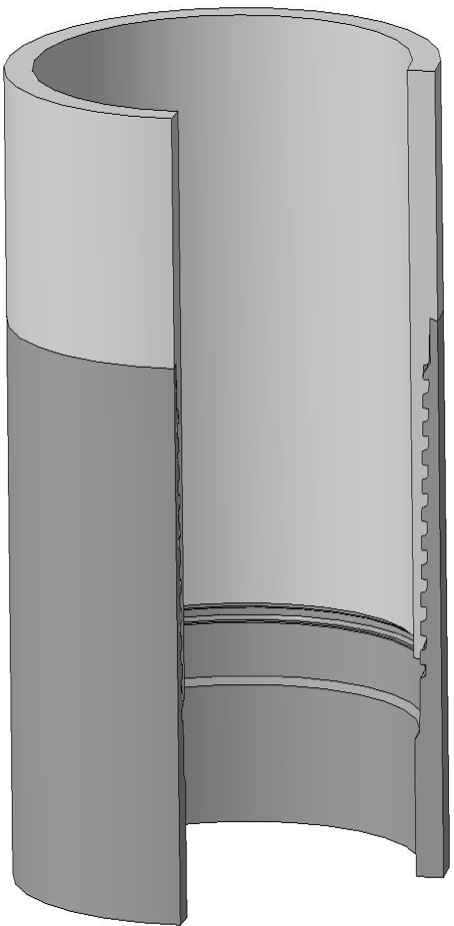

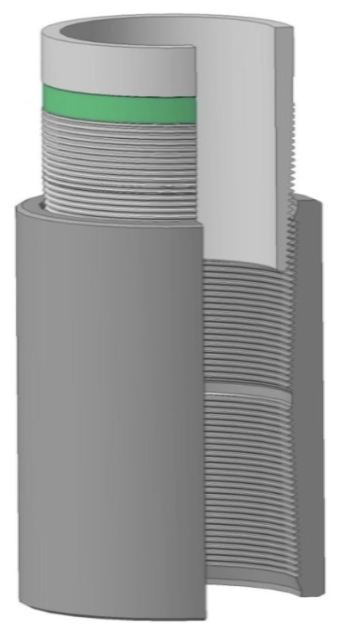

Casing pipes with sleeveless threaded connection OTTM D 102-146 mm

Design advantages:

– low cost of pipe suspension due to the absence of couplings;

– equal passage of the connection;

– additional sealing barrier;

-reducing the cost of restoring casing violations

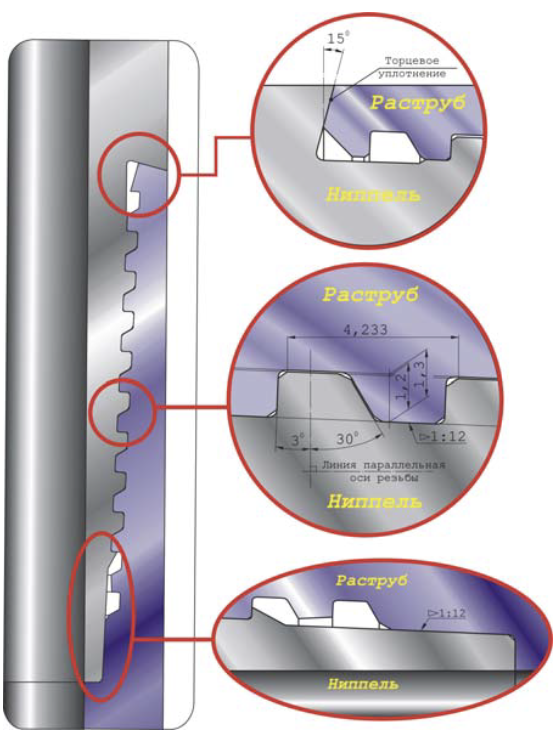

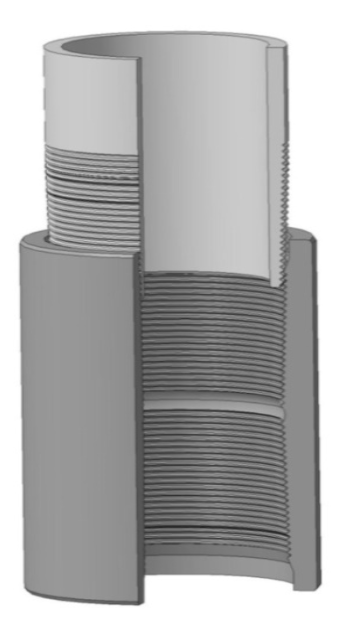

Casing pipes with sleeveless threaded connection “PREMIUM” D 102-146 mm

Purpose:

Designed for casing strings, casing and repair of vertical wells in oil fields.

Pipe size range 102 – 146 mm

Advantages of the NKM-M design:

reduction in the cost of the casing string due to the sleeveless connection

operation in wells with high curvature

outer and inner diameters provide equal passage of the connection

the tightness of the connection is ensured by the presence in the design of the internal radial seal “metal-to-metal”

external conical stop serves as an additional sealing barrier

Tubing pipes with gas-tight threaded connection “PREMIUM” according to specifications D 60-89 mm

Design advantages:

operation in difficult conditions of oil and gas wells;

high torque;

large bending loads;

sealing of the metal-to-metal threaded connection;

high resource

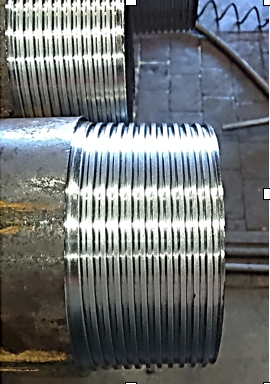

Tubing with high-strength threaded connection for hydraulic fracturing and technological work D 60-89 mm

Standard thread

step 2,54мм

High strength thread

step 3,175 мм

Design advantages:

increase in breaking tensile load by 20% by increasing the length and pitch of the thread;

distortion due to increased free entry of the thread into the coupling;

increase in the guaranteed operating time of a threaded connection for wear up to 25 trips;

reducing the cost of the pipe due to the use of smooth pipes instead of pipes with upset ends (an alternative to NKTV pipes)