Function

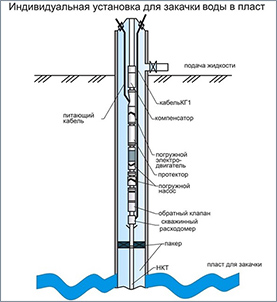

Deterioration in an ecological situation and toughening of environmental standards demand utilization of water which has remained after oil preparation systems. It is possible to solve this problem through pumping water in layer by means of individual installations for PPD.

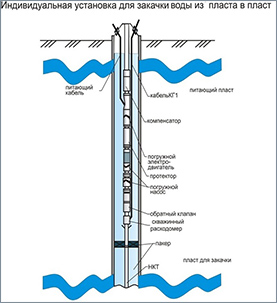

There is a problem of extraction of waters from the high-mineralized Cenomanian levels for production and technological needs.

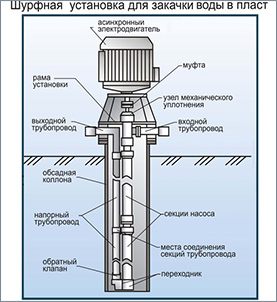

At the moment to solve these problems LLC “Tatoylprom” releases installations for PPD of four types:

- Individual installation for pumping water in layer of “the turned type”.

- Pithy pump installation.

- Pump installation for water extraction from the Cenomanian levels.